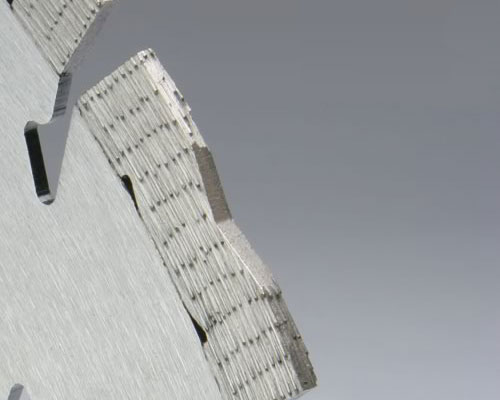

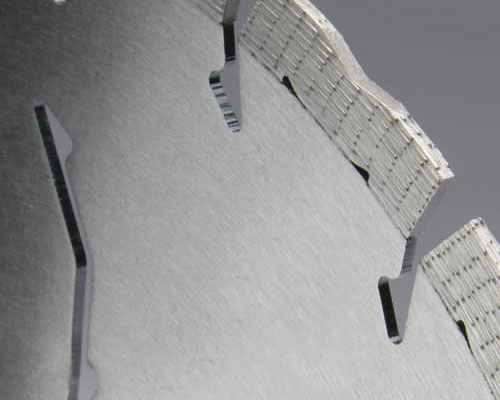

Segment design

Makita introduce new segment designs that are preformed, cold pressed then cured with immense pressure and blistering high temperatures. Each are scrutinised under quality control to exacting standards before being laser welded to the blank ensuring constant reliable performance when used with or without water cooling. Quasar Segments have a fully useable 12mm 'M' shape segment and Comet a10mm stepped segment. The unique segment designs are engineered to improved acceleration into cuts during the initial stage, reduce friction and significantly improve cooling.

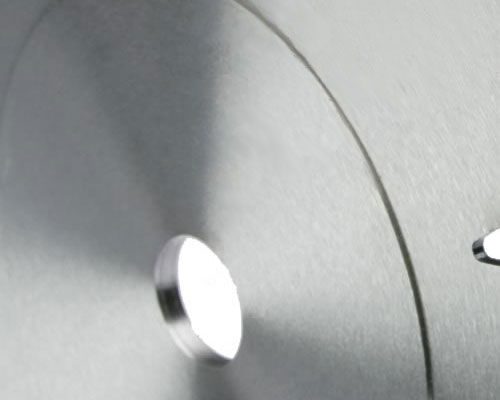

Cooling holes

Keeping a diamond blade cool during operation will help prevent expansion of the blade blank and ensure a smooth cutting action-reducing fatigue for the operator and potential damage to the powertool. The presence of holes in the blade also improves visibility for the user when cutting.

Fixed metal boss

The reinforced centre boss uses a soft metal inner core to dampen vibration through the blade, lowering running noise and guaranteeing an unrivalled quality and ease of cut for the operator. A stable blade cuts cleaner and quicker removing less material and extending blade life-time.

The Cosmos System

Makita now brings a 'universal' approach to blade selection. Advanced segment bonds allow for premium performance across a wider range of materials. Rapide segments for the fastest cut into mid to hard materials and Enduro segments for the longest life in mid to abrasive materials.

3D Diamond Grid

Makita are at the forefront of diamond technology introducing 3D grid diamond arrangement. This advanced method of segment manufacturing allows each diamond grit to be placed in an even 3 dimensional pattern for unparalleled performance against traditional random distribution segments. Value for money is maximized as there is total control over diamond grit positioning meaning lifetime and speed is vastly increased

Stealth

New and advanced technology utilizing laminate blades which reduce resonance and run significantly quieter, especially suited to being used in built-up areas, protecting the public from harmful noise pollution. A steady blade that’s fast and clean cutting.